Non-Destructive Inspection – False Failure Reduction to Enhance Naval Air Station Readiness

Client: Naval Air Systems Command (NAVAIR)

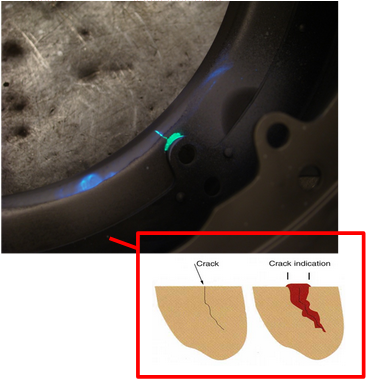

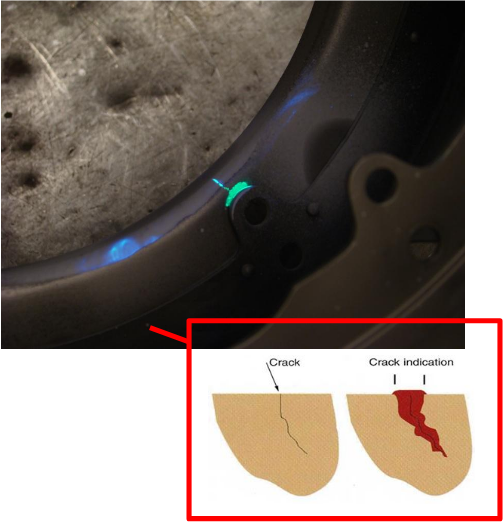

This Lean Six Sigma Black Belt project, conducted at the Non-Destructive Inspection (NDI) work center at Naval Air Station Whidbey Island (FRCNW Work Center 530), focused on reducing false failures during Liquid Penetrant Inspections (LPI). These inspections are critical to identifying cracks in consumable and repairable parts. Approximately 58% of items marked as failures were later determined to be false positives, leading to unnecessary rework, scrapping, and Beyond Capable Maintenance (BCM) actions. The project was led by NOVACES Master Black Belts (MBBs) with support from a cross-functional team of NDI and aviation maintenance personnel.

The Challenge

The NDI shop’s testing inaccuracies were causing significant operational and financial issues. Misidentified failures created excessive turnaround times, manpower waste, and part shortages for mission-critical equipment. False failures resulted in over $376,000 in BCM costs, $16,765 in scrapped parts, and 406 unnecessary rework man-hours annually. Initial analysis showed the inability to confidently distinguish real cracks from false indications due to limitations in equipment and standard inspection procedures.

Solutions Delivered

To address root causes, the project team:

Verified that current practices lacked sufficient optical precision for accurate LPI evaluation.

Recommended procuring advanced optical tools, such as 10X–200X magnifiers, to improve crack detection reliability.

Created a Standard Operating Procedure (SOP) for part induction into the NDI lab, posted visibly and emailed to all supervisors.

Implemented a control plan that includes monthly sustainment reviews, control chart updates, and tracking of false failure candidates and cost.

Assigned Division Green Belts and AIRSpeed Representatives to oversee long-term monitoring and improvement.

Key Takeaways

Estimated cost avoidance of over $393,000 annually through reduction of false failures.

Turnaround time (TRR) reduced by up to 15 days, enhancing readiness for supported work centers.

Improved morale and trust in inspection results by eliminating unnecessary rework and scrap.

Reinforced the importance of appropriate equipment and standard procedures for NDI accuracy.

Created a scalable model for sustaining inspection quality and reducing operational waste.